Top 7 Reasons Why CNC Industrial Machines Are Revolutionizing Global Manufacturing Efficiency

In recent years, the adoption of CNC industrial machines has significantly transformed the landscape of global manufacturing, driving efficiency and precision to unprecedented levels. According to a report by Markets and Markets, the CNC machine market is projected to grow from USD 75 billion in 2020 to over USD 100 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.8%. This explosive growth can be attributed to the increasing demand for automation and the need for enhanced productivity in manufacturing processes.

CNC industrial machines are not only streamlining production workflows but also offering remarkable accuracy and repeatability, which are critical for meeting the stringent quality standards in today's competitive environment. As industries worldwide continue to embrace industrial automation, understanding the benefits and capabilities of CNC industrial machines becomes essential for manufacturers aiming to thrive in this rapidly evolving market.

Understanding CNC Technology: A Game Changer in Manufacturing

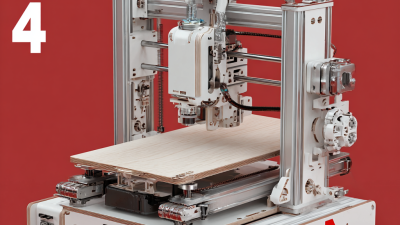

CNC technology, or Computer Numerical Control, is fundamentally transforming the landscape of modern manufacturing. By automating the control of machinery through programmed commands, CNC machines enhance precision and reduce human error. This technology provides unparalleled accuracy in production, allowing manufacturers to create intricate designs with consistent quality. As a result, businesses can produce components that meet exact specifications, which is crucial in industries such as aerospace, automotive, and electronics.

CNC technology, or Computer Numerical Control, is fundamentally transforming the landscape of modern manufacturing. By automating the control of machinery through programmed commands, CNC machines enhance precision and reduce human error. This technology provides unparalleled accuracy in production, allowing manufacturers to create intricate designs with consistent quality. As a result, businesses can produce components that meet exact specifications, which is crucial in industries such as aerospace, automotive, and electronics.

Moreover, the efficiency gains brought about by CNC machines are staggering. Traditional manufacturing methods often require multiple setups and manual adjustments, leading to longer lead times and increased labor costs. CNC machines, however, can operate continuously, thereby significantly reducing production time. Additionally, with advancements in CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing), designers can quickly translate their creative visions into fully functional prototypes. This seamless integration of design and production phases is a game changer, enabling businesses to innovate faster and remain competitive in a rapidly evolving market.

Enhanced Precision and Accuracy: How CNC Machines Transform Production Quality

CNC industrial machines have dramatically transformed the landscape of manufacturing, particularly in terms of

precision and accuracy.

Unlike traditional machining methods, CNC (Computer Numerical Control) technology employs computer systems to dictate the movements of machinery, ensuring that every cut and drill is executed with utmost precision.

This capability allows manufacturers to create complex shapes and intricate designs consistently, resulting in higher-quality products.

The enhanced accuracy not only minimizes waste but also reduces the need for rework, ultimately enhancing the bottom line.

CNC industrial machines have dramatically transformed the landscape of manufacturing, particularly in terms of

precision and accuracy.

Unlike traditional machining methods, CNC (Computer Numerical Control) technology employs computer systems to dictate the movements of machinery, ensuring that every cut and drill is executed with utmost precision.

This capability allows manufacturers to create complex shapes and intricate designs consistently, resulting in higher-quality products.

The enhanced accuracy not only minimizes waste but also reduces the need for rework, ultimately enhancing the bottom line.

Tips: To maximize the benefits of CNC technology, invest in regular training for your operators. Understanding the intricacies of programming and machine operation can lead to even greater levels of precision.

Furthermore, consider maintaining a rigorous check on tool calibration. Regularly inspecting and calibrating tools will ensure that they remain sharp and effective, leading to superior product quality.

In addition, integrating advanced software solutions with CNC machines can further optimize production efficiency.

These systems can analyze data in real-time, providing insights into manufacturing processes and enabling quicker adjustments as necessary.

By embracing these smart technologies alongside CNC operations, manufacturers can achieve an unprecedented level of accuracy and operational excellence.

Tips: Employing simulation software before actual production helps identify potential issues and streamline designs, resulting in more efficient manufacturing processes.

Always keep communication lines open between the design and production teams to align objectives and maintain high-quality standards throughout the production cycle.

Increased Production Speed: The Impact of CNC Machines on Manufacturing Throughput

CNC industrial machines have become pivotal in enhancing manufacturing throughput, substantially increasing production speed across various sectors. By automating tasks that were traditionally labor-intensive, CNC technology allows manufacturers to produce intricate components with unmatched precision and efficiency. This capability not only accelerates the production timeline but also minimizes the risk of human error that can lead to costly delays.

To maximize the benefits of CNC machines, it’s essential for manufacturers to invest in proper training for their operators. Well-trained personnel can fully leverage the machine's capabilities, optimizing workflow and reducing downtime. Additionally, regular maintenance of CNC equipment is crucial; keeping machines in top condition prevents unexpected breakdowns and ensures consistent production speeds.

Moreover, incorporating advanced CAD/CAM software can significantly streamline the design-to-production process. By enabling faster programming and quicker adjustments, businesses can respond swiftly to market demands, fulfilling orders with increased agility. This flexibility helps manufacturers stay competitive in a fast-paced global market, demonstrating that embracing CNC technology is not just about speed but also about strategic adaptation to evolving business landscapes.

Top 7 Reasons Why CNC Industrial Machines Are Revolutionizing Global Manufacturing Efficiency

| Reason | Impact on Production Speed | Efficiency Improvement (%) | Production Throughput (Units/Hour) |

|---|---|---|---|

| Higher Precision | Reduces errors in production | 30% | 300 |

| Automation | Minimizes manual intervention | 40% | 500 |

| Reduced Setup Time | Faster tool changes | 25% | 450 |

| Increased Flexibility | Easily switch between tasks | 35% | 400 |

| Improved Material Utilization | Less waste generated | 20% | 350 |

| Consistent Quality | Uniform output standards | 45% | 550 |

| Reduced Labor Costs | Fewer workers needed for manufacturing | 50% | 600 |

Cost Efficiency and Waste Reduction: Economic Benefits of CNC Machinery in Production

The integration of CNC (Computer Numerical Control) industrial machines in manufacturing processes has significantly enhanced cost efficiency and waste reduction in production. These machines utilize precise programming to automate and streamline operations, which minimizes human error and optimizes resource allocation. By improving accuracy, CNC machinery ensures that materials are used more effectively, leading to less scrap and rework. This has a direct impact on lowering production costs and enhancing overall profitability for businesses.

One effective tip for maximizing the economic benefits of CNC machinery is to invest in employee training. Proper training ensures that staff can operate CNC machines to their full potential, minimizing downtime and maximizing output. A well-trained workforce can also identify opportunities for further efficiency improvements, ultimately resulting in better resource management.

Another important consideration is routine maintenance. Keeping CNC machines in peak condition not only prolongs their lifespan but also enhances their performance, which directly contributes to cost savings. Simple practices like regular calibration and prompt servicing can prevent costly breakdowns and inefficiencies, allowing manufacturers to maintain a competitive edge in a rapidly evolving market.

Impact of CNC Machinery on Manufacturing Efficiency

Versatility in Manufacturing: Applications of CNC Machines Across Different Industries

CNC machines have become a cornerstone of modern manufacturing across various industries due to their exceptional versatility. From automotive to aerospace, these advanced systems enable precise, automated processes that significantly boost product quality and reduce time-to-market. According to a report by the International Federation of Robotics, the use of CNC technology in industrial settings has led to a productivity increase of approximately 30% over the last decade. This efficiency translates into substantial cost savings and enhanced operational capabilities for manufacturers.

Another compelling application of CNC machines is in the realm of maintenance operations. Advanced machine learning systems have been developed to evaluate essential maintenance processes, including tool wear monitoring in CNC machine tools. By leveraging predictive analytics, companies can anticipate maintenance needs and avoid unexpected downtime, which the National Institute of Standards and Technology estimates can cost manufacturers up to $260,000 per hour. Such innovations not only improve the reliability of CNC operations but also contribute to a more sustainable manufacturing ecosystem, where resources are optimized and waste is minimized.

Related Posts

-

7 Amazing Features of the Best 3D CNC Machine You Need to Know

-

Unveiling the Technical Specifications of the Best CNC Machine for Precision Engineering

-

Unlocking the Future of Best CNC Machine Industrial in 2025 Strategies for Global Buyers

-

Top Strategies for Choosing the Best CNC Router for Your Business Needs

-

Understanding Import Export Certifications for Buying the Best CNC Laser Cutter Globally

-

Global Leaders in Manufacturing Unveiling the Best Industrial CNC Solutions