Unlocking Creativity with CNC Wood Carving Machines and Their Unique Advantages

In recent years, the rise of the CNC wood carving machine has revolutionized the woodworking industry, unlocking unprecedented levels of creativity and efficiency. According to a report by Research and Markets, the global CNC machine market is projected to reach $117 billion by 2026, with wood carving machines representing a significant portion of this growth due to their versatility and precision. These machines not only streamline the design process but also allow artisans to achieve intricate details that were once labor-intensive and time-consuming. As innovations in technology continue to evolve, the CNC wood carving machine stands out as an essential tool for both hobbyists and professionals alike, enabling them to transform their creative visions into tangible works of art with remarkable ease.

Exploring the Basics of CNC Wood Carving Machines and Their Functionality

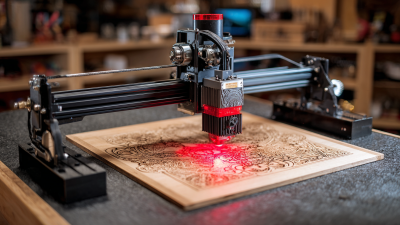

CNC wood carving machines offer a transformative approach to creativity in woodworking. By leveraging advanced technology, these machines utilize computer numerical control to accurately carve intricate designs and patterns into wood, enhancing both precision and efficiency. As the demand for customized and high-value products grows, CNC machines provide woodworkers with the ability to produce unique items at scale, catering to the evolving tastes of consumers.

The functionality of CNC wood carving machines revolves around their ability to execute complex designs with minimal manual intervention. Operators can create detailed models in software, which the CNC machine then translates into physical carvings. This digital approach not only streamlines the production process but also opens up new avenues for artistic expression.

Trends point to a significant growth in the CNC market, driven by innovations that make these machines more accessible and versatile, establishing them as essential tools for modern creators seeking to push the boundaries of traditional woodworking.

Understanding the Unique Advantages of CNC Technology in Creative Projects

CNC (Computer Numerical Control) technology has revolutionized the woodworking industry, offering unique advantages that significantly enhance creative projects. One of the standout benefits of CNC wood carving machines is their precision. According to a report by TechNavio, the global CNC machine market is expected to grow by 4.12 billion USD from 2020 to 2024, a testament to the increasing adoption of this technology in creative fields. This precision allows artisans to execute intricate designs with repeatable accuracy, enabling them to push the boundaries of their craft and explore complex patterns that would be daunting or impossible with traditional methods.

Moreover, CNC machines enhance the production speed of creative projects. The same report highlights that automation through CNC technology can increase production efficiency by up to 70%. This efficiency not only reduces time spent on repetitive tasks but also enables creators to focus more on the design and innovation aspects of their work. With access to a quick turnaround time, artists and designers can engage in more exploratory and iterative processes, ultimately unlocking greater creativity and enabling the realization of bold ideas that dominate today’s dynamic design landscape.

Step-by-Step Guide to Getting Started with CNC Wood Carving

Getting started with CNC wood carving can be an exciting journey, allowing you to unlock your creativity and transform your ideas into tangible art. First, it’s essential to choose the right CNC machine that fits your project needs and budget. Consider the size of the workspace, the materials you plan to use, and the types of designs you want to create. Popular choices include router-based machines for beginners, as they are user-friendly and versatile.

Tip: Before diving into your first project, familiarize yourself with the software that comes with your CNC machine. Many machines offer tutorials and community forums which can be invaluable for learning the ins and outs of design and operation.

Next, sourcing high-quality wood is crucial for achieving the best results. Look for materials that are easy to carve and have the desired finish. Hardwoods like oak or maple can lend a beautiful look but may require more advanced technique.

Tip: Always conduct test runs on scrap pieces of wood to dial in the settings and get comfortable with the machine’s carving speed and depth before applying it to your final piece. With practice and patience, you can produce stunning works of art that showcase your unique vision and style.

Tips for Designing Custom Projects with CNC Wood Carving Software

CNC wood carving machines are revolutionizing the way creatives approach custom projects. With their precision and versatility, these machines empower users to bring intricate designs to life, making them essential tools for makers and hobbyists alike. Data shows that the popularity of CNC machines is steadily increasing within these communities, as they allow for the creation of complex components and detailed artistic expressions.

When designing custom projects, utilizing CNC wood carving software can significantly enhance the workflow. Here are a few tips to optimize your design process: First, familiarize yourself with various design software options that cater to CNC carving, as these can streamline your design-to-production pipeline. Second, take advantage of online resources that offer CNC furniture plans; these can provide inspiration and practical templates for your projects. Lastly, consider experimenting with different types of wood and finishes to discover unique textural contrasts in your work, enabling you to create standout pieces.

Incorporating the insights gained from the growing trend of CNC applications can lead to innovative designs that not only fulfill personal creative visions but also tap into lucrative markets. As the demand for custom CNC projects rises, understanding the capabilities of CNC wood carving machines becomes paramount in unlocking your creative potential.

Unlocking Creativity with CNC Wood Carving Machines and Their Unique Advantages

| Advantages | Description | Applications |

|---|---|---|

| Precision | CNC machines offer high accuracy, ensuring intricate designs are replicated perfectly. | Furniture design, intricate decor items. |

| Efficiency | Able to produce designs quickly, reducing production time significantly. | Mass production of wooden products. |

| Versatility | Can work with various materials, allowing for diverse range of projects. | Sign making, model making, artistic sculptures. |

| Design Flexibility | Allows for easy modifications and custom designs without retooling costs. | Custom art pieces, personalized gifts. |

| Reduced Labor Costs | Automating processes lowers the need for manual labor. | Small business operations and startups. |

Maximizing Creativity: Best Practices for Using CNC Wood Carving Machines

Harnessing the power of CNC wood carving machines opens up a world of creative possibilities for artisans and hobbyists alike. To truly maximize creativity with these sophisticated tools, it's essential to adopt best practices that enhance both design and execution. One effective strategy is to begin with a clear vision of the desired outcome. Sketching ideas or using design software not only aids in visualizing the project but also simplifies the process of translating those ideas into digital formats compatible with CNC machines.

In addition, it’s crucial to familiarize oneself with the software and hardware of the CNC machine. Understanding the capabilities and limitations of your equipment can greatly influence the creative process. Utilizing higher-quality materials and proper bit selection can also enhance the intricacy and finish of the designs. Regularly experimenting with different techniques, such as varying depths of cut or speeds, allows creators to discover unique textures and shapes that can set their work apart. By integrating these practices into the workflow, woodworkers can unlock a new realm of creativity, transforming simple ideas into stunning, tangible art.

Unlocking Creativity with CNC Wood Carving Machines

Related Posts

-

How to Choose the Best CNC Wood Carving Machine: A Comprehensive Tutorial for Buyers

-

China's Premier CNC Wood Cutting Machines Setting Global Standards in Quality and Innovation

-

Top Strategies for Sourcing the Best CNC Wood Carving Machines Worldwide

-

10 Reasons the Best CNC Laser Engraver Will Transform Your Business

-

Global Leaders in Manufacturing Unveiling the Best Industrial CNC Solutions

-

Unveiling the Technical Specifications of the Best CNC Machine for Precision Engineering