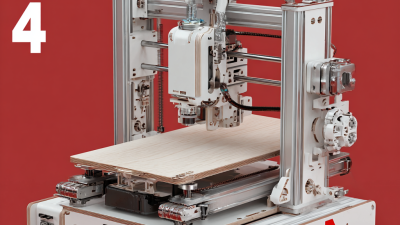

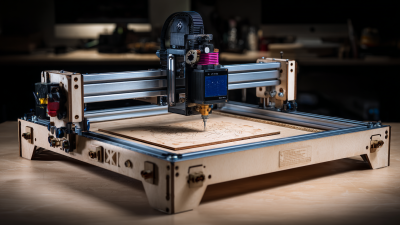

7 Digital Innovations Transforming the Best 3D CNC Machines for Precision Manufacturing

In the era of rapid technological advancement, the manufacturing industry is undergoing a transformative shift, driven by digital innovations that enhance precision and efficiency. One of the standout developments in this landscape is the evolution of the 3D CNC machine, which combines computer numerical control with three-dimensional printing capabilities. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $117.9 billion by 2025, growing at a CAGR of 6.6%. This surge is largely attributed to the increasing demand for highly accurate components in sectors such as aerospace, automotive, and healthcare. As manufacturers strive for greater production capabilities and reduced lead times, the integration of advanced technologies like AI, IoT, and cloud computing into 3D CNC machines is not just a trend but a necessity. This ultimate guide will explore seven key digital innovations that are revolutionizing the landscape of precision manufacturing and shaping the future of 3D CNC machinery.

Impact of IoT on Enhancing CNC Machine Precision and Efficiency

The integration of the Internet of Things (IoT) in CNC machines is marking a revolutionary shift in precision manufacturing. As manufacturers look to enhance operational accuracy and efficiency, the connectivity provided by IoT allows for real-time data analysis and monitoring. This results in improved machine performance and reduced downtime, which is crucial in a competitive market where precision is paramount.

Recent trends indicate that the ultra-precision machining technology market is set to grow significantly, reflecting an industry-wide shift towards smarter manufacturing. The forecasted expansion—from USD 6.24 billion in 2024 to USD 11.25 billion by 2033—highlights the increasing reliance on technologies that facilitate adaptable and efficient production settings. Additionally, the incorporation of digital twins in manufacturing processes is enhancing predictive maintenance and operational efficiency, providing manufacturers with a strategic advantage in optimizing performance and minimizing costs.

With collaborative robots (cobots) redefining how automation is perceived, the landscape of manufacturing is rapidly changing. By working alongside human operators, cobots are revolutionizing flexible manufacturing solutions and enabling high-precision tasks across various sectors. As these technologies continue to evolve, they will play a critical role in shaping the future of CNC machining and precision manufacturing.

AI-Driven Algorithms: Revolutionizing CAD Designs for Better Manufacturing

Artificial Intelligence (AI) is significantly transforming the landscape of Computer-Aided Design (CAD) in precision manufacturing, particularly within the realm of 3D CNC machines. Recent studies indicate that AI-driven algorithms can improve design efficiency by up to 75%, enabling engineers and designers to create more complex geometries while minimizing errors. According to a report from McKinsey & Company, companies leveraging AI in their design processes have seen a 30% increase in productivity and a 20% reduction in time-to-market for new products. This shift toward intelligent design automation not only enhances precision but also empowers manufacturers to meet the increasing demand for customized solutions.

Moreover, integrating AI algorithms facilitates generative design, a process where machines can suggest optimal design structures based on predefined parameters. This innovative approach allows for the exploration of numerous design alternatives that a human designer might overlook, thereby fostering innovation. A report by Deloitte highlighted that organizations adopting generative design techniques are likely to achieve a 25% reduction in materials used while ensuring structural integrity is maintained. As AI continues to reshape CAD methodologies, the importance of these advancements will be evident in the precision and efficiency of 3D CNC machining, ultimately redefining what is possible in manufacturing.

Integrating Augmented Reality for Remote CNC Machine Monitoring

The integration of augmented reality (AR) into CNC machine monitoring represents a groundbreaking shift in precision manufacturing. By overlaying digital information onto the physical world, AR allows operators to visualize machine performance and diagnostics in real-time. This technology enhances the user experience, providing intuitive insights into machine operations. With AR goggles or mobile apps, technicians can swiftly assess the status of CNC machinery, troubleshoot issues, and determine the next steps without interrupting production flows.

Moreover, augmented reality fosters collaboration among remote teams, transcending geographical barriers. Experts can guide on-site operators through complex setups or repairs by sharing their AR view, making problem-solving far more efficient. This real-time interaction reduces downtime and enhances training opportunities, as novices can learn from seasoned professionals' insights. The result is not only improved operational efficiency but also a significant elevation in the skill set of the workforce. As CNC machines continue to evolve, the adoption of AR will undoubtedly play a critical role in shaping the future of precision manufacturing.

Smart Sensors: The Future of Predictive Maintenance in CNC Technology

Smart sensors are revolutionizing the world of CNC technology, particularly in the realm of predictive maintenance. These advanced systems leverage real-time data to monitor the condition of CNC machines, allowing manufacturers to foresee potential issues before they escalate into expensive breakdowns. By integrating smart sensors, companies can significantly reduce downtime and enhance the overall efficiency of their manufacturing processes.

When implementing smart sensors, consider using vibration analysis and temperature monitoring, as they are crucial for tracking machine health. Regularly updating your sensor software can also ensure that you are benefiting from the latest predictive analytics capabilities. Additionally, utilizing cloud-based platforms can facilitate better data storage and access, enabling teams to make informed decisions swiftly.

Investing in smart sensors not only improves operational efficiency but also promotes a culture of proactive maintenance within your organization. Encourage your team to analyze the data collected to identify patterns that may indicate wear and tear. Implementing a routine check based on these insights can extend the life of CNC machines and enhance productivity in the long run.

Impact of Digital Innovations on Precision Manufacturing

Cloud Computing: Streamlining Workflow for CNC Precision Engineering

Cloud computing has become a game changer in the realm of CNC precision engineering, offering manufacturers the ability to streamline workflows and enhance operational efficiency. According to a report by MarketsandMarkets, the cloud computing market in manufacturing is expected to grow from $12.7 billion in 2020 to $35.0 billion by 2025, reflecting a compound annual growth rate (CAGR) of 22.5%. This surge indicates a growing reliance on cloud solutions to manage complex CNC machining processes, enabling real-time data access and collaboration across teams.

Integrating cloud computing into CNC precision engineering allows for improved data collection and analysis, leading to better decision-making and reduced downtime. For instance, with cloud solutions, manufacturers can monitor CNC machine performance in real-time, predict maintenance needs, and leverage big data analytics to fine-tune machining parameters. According to a study by McKinsey, companies that fully utilize data-driven decision-making capabilities see a productivity boost of 5-6%. The ability to innovate processes while managing resources more effectively ensures that organizations remain competitive in an increasingly digital landscape.

7 Digital Innovations Transforming the Best 3D CNC Machines for Precision Manufacturing

| Innovation | Description | Impact on CNC Precision | Benefits |

|---|---|---|---|

| Cloud Computing | Utilizing cloud services for data storage and access. | Enhances collaboration and accessibility of design files. | Increased efficiency and reduced downtime. |

| AI-Powered Automation | Implementing AI for auto-adjustment of CNC parameters. | Improves machining accuracy and speeds up production times. | Higher quality output and reduced operator intervention. |

| IoT Integration | Connecting CNC machines to the Internet for real-time data monitoring. | Real-time feedback for preventive maintenance and performance optimization. | Minimized unexpected failures and reduced maintenance costs. |

| Simulation Software | Advanced software for virtual machining before actual production. | Allows for fine-tuning of designs and processes. | Saves time and reduces material waste. |

| Augmented Reality (AR) | Using AR for real-time troubleshooting and training. | Facilitates skill development and enhances operational efficiency. | Reduces training time and enhances user experience. |

| Digital Twin Technology | Creating a virtual duplicate of physical assets for monitoring and analysis. | Offers insights into performance and predictive maintenance. | Optimizes operations and extends the lifespan of machines. |

| Blockchain for Supply Chain | Applying blockchain for secure and transparent manufacturing processes. | Improves traceability and reduces fraud risks. | Enhances trust and accountability within the supply chain. |

Related Posts

-

Exploring the Future of Best CNC Engraving Machines in 2025 and How to Choose the Right One

-

7 Amazing Features of the Best 3D CNC Machine You Need to Know

-

The Ultimate Guide to Choosing the Best CNC Machine for Your Home Workshop

-

Unlocking the Future of Best CNC Machine Industrial in 2025 Strategies for Global Buyers

-

China's Premier CNC Wood Cutting Machines Setting Global Standards in Quality and Innovation

-

Exploring the Top Alternatives to the Best CNC Laser Engraver for Your Business Needs