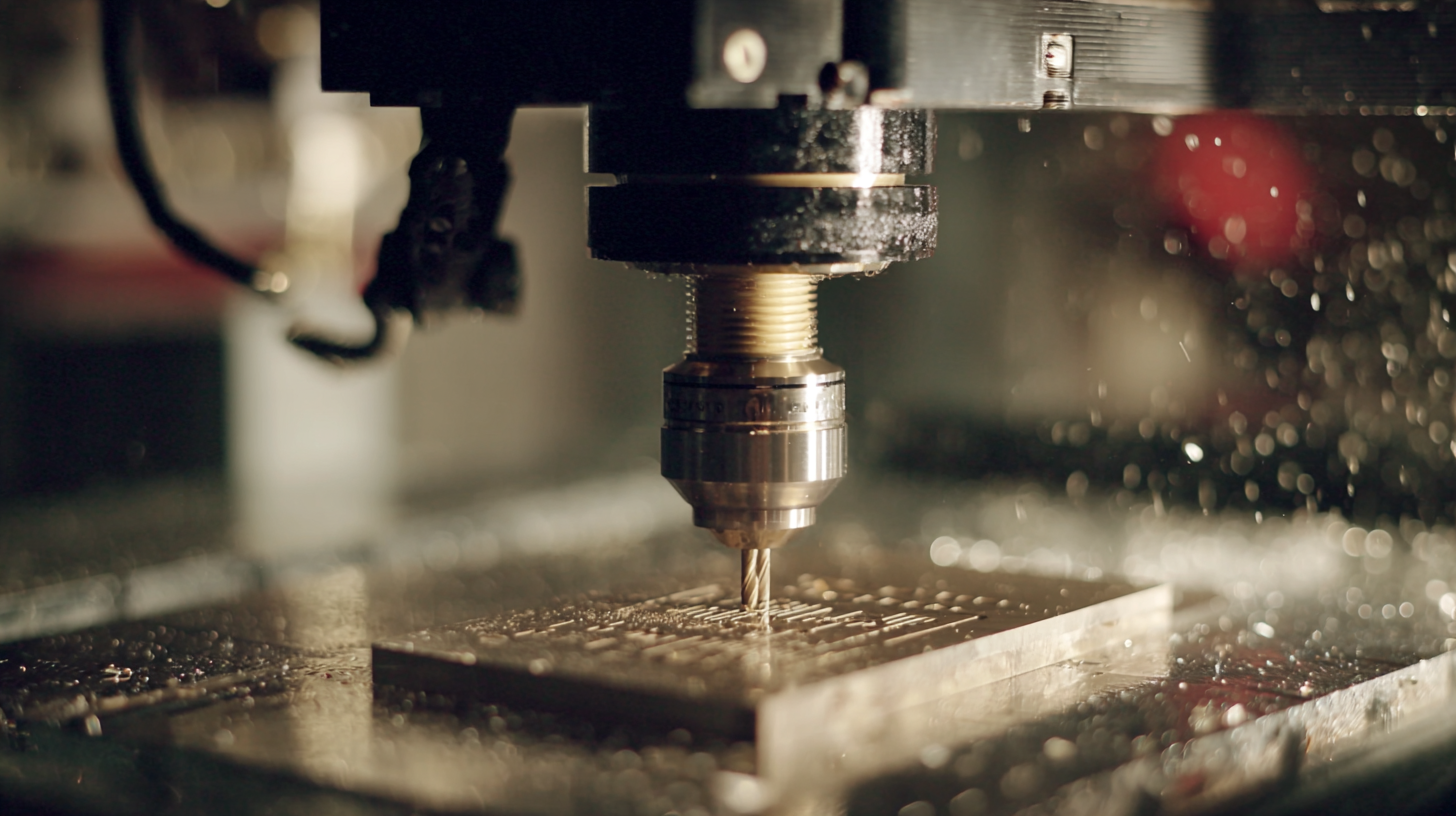

Exploring the Future of Best CNC Engraving Machines in 2025 and How to Choose the Right One

As we venture into 2025, the landscape of manufacturing technology is rapidly evolving, particularly in the realm of CNC engraving machines. According to a report by Markets and Markets, the global CNC machine market is expected to reach $117.89 billion by 2025, driven by advancements in automation and precision engineering. This surge is indicative of the increasing demand for high-quality engraving solutions across diverse industries, from automotive to aerospace. The right CNC engraving machine not only enhances productivity but also offers unparalleled accuracy and versatility in design. As businesses strive to optimize their operations, understanding the key features and innovations in CNC engraving machines will be crucial in selecting the optimal equipment for specific applications. In this blog, we will explore the future trends of these machines and provide insights on how to choose the right one to meet your engraving needs.

The Evolution of CNC Engraving Machines: Trends to Watch for in 2025

The landscape of CNC engraving machines is evolving rapidly, driven by advancements in technology and shifting market demands. As we look ahead to 2025, several key trends are poised to shape the industry. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025, with a significant portion attributed to engraving machines. This growth indicates a rising demand for precision and efficiency, prompting manufacturers to innovate and integrate advanced features.

One notable trend is the increasing incorporation of artificial intelligence and machine learning in CNC engraving machines. These technologies enhance the machines' capabilities, allowing for real-time adjustments and improved engraving quality. In fact, a recent survey indicated that 45% of manufacturers are investing in AI technologies for their CNC equipment by 2025. Additionally, sustainable manufacturing practices are becoming more prevalent, with the demand for eco-friendly materials and energy-efficient machines on the rise. As industry leaders prioritize sustainability, the development of CNC machines that utilize recycled materials and minimize waste will likely become a significant focus heading into 2025.

Key Features to Consider When Choosing Your CNC Engraving Machine

When selecting the right CNC engraving machine, several key features must be considered to ensure optimal performance for your specific projects. First, assess the machine's power and precision. For instance, modern laser engravers are designed to handle various materials, including wood, acrylic, and leather, demonstrating versatility essential for crafts and manufacturing. The engraving speed and build area are also critical; higher speed allows for more efficient production, while a larger build area accommodates bigger projects.

**Tip:** Always look for compatibility with software systems that enhance usability, such as LightBurn for laser engravers or GRBL for CNC machines. Such software can significantly improve your workflow and the intricacy of your designs.

Another crucial aspect is the spindle motor quality. A high-quality spindle ensures smoother operation, reducing wear and tear while also enhancing the precision of engravings. Recent reports suggest that investing in robust spindle options can lead to longer machine life and better outputs.

**Tip:** Consider the after-sales support and community that comes with the machine. Engaging with a solid user community can provide valuable insights and solutions for common operational challenges, making your engraving experience smoother and more rewarding.

Comparative Analysis: Top CNC Engraving Machines of 2025

As we explore the future of CNC engraving machines in 2025, it’s crucial to conduct a comparative analysis of the top options available on the market. The engraving landscape is rapidly evolving, with the laser processing market projected to grow from USD 7.17 billion in 2025 to USD 11.89 billion by 2032, reflecting a compound annual growth rate (CAGR) of 8.5%. This growth is driven by a surge in demand for precision and versatility in engraving solutions, especially among hobbyists and small business owners.

When choosing the right CNC engraving machine, consider factors such as technology, ease of use, and application suitability. For example, laser engraving has transitioned from a niche industrial service to a widely accessible tool for personalized products, with the engraving services industry expected to reach $432.32 million by 2030. This indicates a strong market trend towards customization and artistic creativity within engraving.

**Tips:**

1. Evaluate your specific needs: Identify whether you need high speed, precision, or versatility in design to guide your choice of machine.

2. Look for user-friendly interfaces: Machines with intuitive controls can significantly enhance your engraving experience, especially if you are new to CNC technology.

3. Assess future market trends: Staying informed about projected market growth can help in selecting machines that will remain relevant and reliable in the coming years.

Comparative Analysis of CNC Engraving Machines in 2025

Maximizing Efficiency: Tips for Optimal CNC Engraving Performance

Maximizing efficiency in CNC engraving is crucial for both amateur and professional users. As the CNC engraving industry is projected to grow to $7.5 billion by 2025, understanding how to optimize your engraving process becomes more important than ever. With advancements in technology, machines are becoming faster and more precise, which allows for increased production rates and improved product quality.

To achieve optimal CNC engraving performance, consider the following tips:

- Ensure that you select the right bit for your material. Studies indicate that using a bit specifically designed for your engraving material can enhance detail and decrease tool wear, improving overall efficiency.

- Maintain a clean workspace and regularly service your machine. A well-maintained CNC machine operates more smoothly, reducing downtime and ensuring consistent results.

Finally, invest in good software that complements your CNC equipment. According to a recent market analysis, efficient software can increase engraving speeds by up to 30%, thus significantly improving your output. By applying these strategies, not only can you enhance your engraving efficiency, but you can also position yourself for success in the expanding CNC engraving market.

Future-Proofing Your Business: Investing in Advanced CNC Technology

As technology continues to advance at an unprecedented pace, investing in advanced CNC (Computer Numerical Control) engraving machines is essential for businesses aiming to remain competitive in 2025 and beyond. Future-proofing your operations requires a strategic focus on the capabilities and features that the latest CNC machines offer. These include enhanced precision, speed, and automation, which can significantly elevate the quality of your output while reducing operational downtime. By selecting machines with the latest technology, businesses can ensure they are equipped to handle the growing demands of diverse industries.

Moreover, when choosing the right CNC engraving machine, consider factors such as compatibility with various materials, ease of use, and software integration. Opting for machines that offer advanced features, such as adaptive machining and smart connectivity, will not only streamline your production processes but also make it easier to adapt to market changes. Investing in training for your team to operate these advanced machines effectively can also contribute to maximizing the return on your investment. Ultimately, the right CNC technology can propel your business forward, ensuring that you remain at the forefront of innovation in your industry.