Top 10 Woodworking CNC Machines for Precision and Creativity in Your Projects

In the realm of creative craftsmanship, the advent of technology has revolutionized the woodworking industry, particularly with the introduction of woodworking CNC machines. These sophisticated tools have become indispensable for both amateur woodworkers and seasoned professionals, enabling precision and intricate design execution that was once solely reliant on manual techniques. With the ability to transform creative visions into tangible realities, woodworking CNC machines open up a world of possibilities, allowing for both artistic expression and functional innovation.

As we explore the top 10 woodworking CNC machines, it becomes clear that these devices cater to a diverse range of woodworking projects. From detailed carvings to complex joinery, they provide unparalleled accuracy and repeatability. By automating the cutting process, woodworkers can allocate their time and energy towards honing their design ideas and enhancing their skill sets. With this guide, you will discover the best woodworking CNC machines that blend technology and artistry, helping to elevate your projects beyond traditional craftsmanship to new heights of creativity and precision.

Overview of CNC Machines in Woodworking

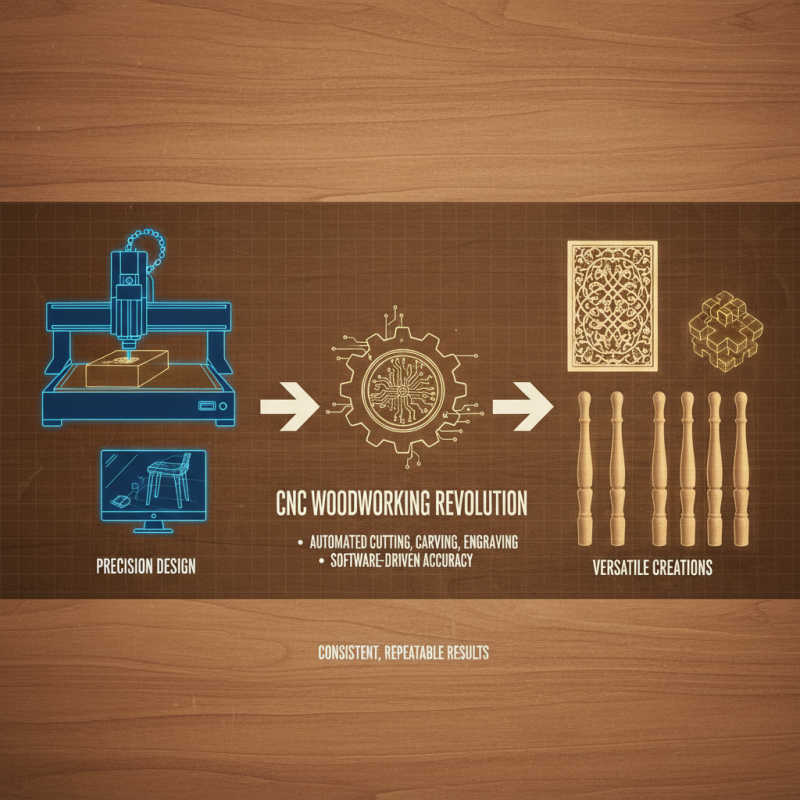

CNC machines have revolutionized the woodworking industry by combining precision with versatility. These computer-controlled tools allow woodworkers to create intricate designs and shapes that would be exceedingly difficult or impossible to achieve manually. Using software to design their projects, craftsmen can automate the cutting, carving, and engraving processes, leading to consistent and repeatable results. This level of accuracy is especially beneficial for both small-scale artisans and larger manufacturers who require uniformity in their products.

Moreover, the integration of CNC technology in woodworking enhances creativity by allowing users to experiment with complex patterns and elaborate designs. The ability to manipulate digital models means that woodworkers can push the boundaries of traditional crafting, transforming their ideas into reality with remarkable detail. As woodworking continues to evolve, CNC machines stand out as a vital tool, offering both professional and hobbyist woodworkers a means to explore new artistic possibilities and streamline their production workflows.

Key Features to Look for in Woodworking CNC Machines

When selecting a woodworking CNC machine, several key features are crucial to ensure the best performance for your projects. First and foremost, precision is vital. Look for machines that offer high-resolution stepper or servo motors, as they enable intricate designs and exact cuts. The accuracy of the machine will determine how closely the final product matches your design specifications, impacting both functionality and aesthetics.

Another important aspect to consider is the versatility of the CNC machine. A good woodworking CNC should support various materials, including hardwood, softwood, and even composite materials. Check for compatibility with different bit types and sizes, as this flexibility allows you to tackle a broader range of projects. Additionally, a user-friendly software interface can enhance creativity, enabling both seasoned woodworkers and beginners to easily manipulate designs and execute complex patterns.

Furthermore, pay attention to the build quality and stability of the machine. A robust and durable construction will minimize vibrations and ensure smooth operation, offering enhanced cut quality. A machine with a larger working area will also allow you to handle bigger projects without the constraints of material size. Overall, by focusing on these essential features, you can find a woodworking CNC machine that meets your creative needs while delivering precision and reliability.

Top 10 Woodworking CNC Machines Performance Comparison

This bar chart illustrates the performance metrics of various woodworking CNC machines, focusing on precision and creativity in projects. The data reflects features such as maximum cutting speed, precision level (in mm), and the number of available axes.

Top 10 Woodworking CNC Machines Reviewed

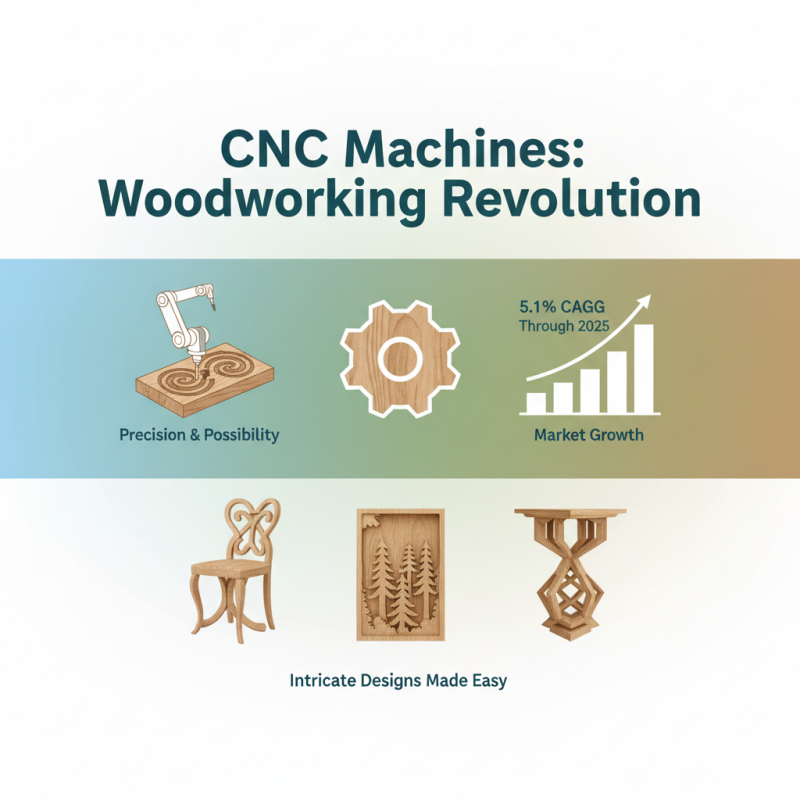

In the realm of woodworking, precision and creativity are paramount, and the rise of CNC (Computer Numerical Control) technology has revolutionized this craft. According to a report by MarketsandMarkets, the CNC machine tools market is projected to reach $100 billion by 2025, driven by the growing demand for automation in various manufacturing sectors, including woodworking.

The expansive capabilities of modern CNC machines allow artisans and manufacturers to achieve intricate designs and consistent quality in their projects, making them indispensable tools for both hobbyists and professionals alike.

When it comes to selecting the right CNC machine for woodworking, key features such as cutting speed, precision, and user-friendly interfaces should be considered. Various studies indicate that machines offering scalability and versatility in project sizes tend to attract more users. For instance, the woodworking industry has seen an increased preference for CNC devices with advanced software integration capabilities, facilitating seamless design-to-production workflows. Automation in woodworking not only enhances productivity but also opens new avenues for creativity, enabling woodworkers to push the boundaries of their craft.

Moreover, the precision offered by these machines minimizes material waste, contributing to both cost efficiency and sustainability in woodworking practices.

Comparison of Price and Performance Among CNC Models

When selecting a CNC machine for woodworking, it's essential to consider both price and performance to ensure you are making a wise investment. Numerous models are available, each offering a unique balance of features that cater to different project needs. In this competitive market, the primary distinction often lies in the quality of materials used, motor strength, and software compatibility. Lower-priced models may appeal to hobbyists, but they can fall short on precision or durability, which are crucial for more complex tasks.

High-performance CNC machines typically come at a higher price point but provide advanced capabilities such as faster cutting speeds, greater accuracy, and enhanced versatility. These models often support various software applications, allowing for intricate designs and easier programming. While the initial investment may be significant, the long-term value of craftsmanship and efficiency can justify the cost for professionals. Ultimately, understanding the trade-offs between cost and the operational capabilities of various CNC machines is key to making an informed choice that aligns with your woodworking goals.

Top 10 Woodworking CNC Machines for Precision and Creativity in Your Projects - Comparison of Price and Performance Among CNC Models

| Model | Cutting Area (inches) | Spindle Power (W) | Max Speed (ipm) | Price (USD) |

|---|---|---|---|---|

| CNC Model A | 24 x 36 | 1500 | 120 | $2,500 |

| CNC Model B | 30 x 48 | 2000 | 150 | $3,200 |

| CNC Model C | 36 x 60 | 2400 | 180 | $4,500 |

| CNC Model D | 48 x 96 | 3000 | 200 | $5,800 |

| CNC Model E | 42 x 42 | 1800 | 130 | $2,900 |

| CNC Model F | 36 x 36 | 1000 | 100 | $1,500 |

| CNC Model G | 25 x 38 | 2200 | 160 | $3,700 |

| CNC Model H | 32 x 32 | 1600 | 140 | $2,200 |

| CNC Model I | 40 x 60 | 2700 | 175 | $4,200 |

| CNC Model J | 20 x 30 | 900 | 80 | $1,000 |

Creative Applications of CNC Machines in Woodworking Projects

CNC (Computer Numerical Control) machines have revolutionized the woodworking industry, offering unprecedented precision and a vast array of creative possibilities. As detailed in a recent industry report by the Freedonia Group, the market for CNC machines is projected to grow at a compound annual growth rate (CAGR) of 5.1% through 2025, driven by advancements in technology and increasing demand for custom woodworking projects. These machines allow woodworkers to produce intricate designs and shapes that would be nearly impossible to achieve by hand.

One of the most creative applications of CNC technology in woodworking is the ability to create customized furniture pieces. Designers can bring their unique visions to life with tailor-made designs, enhancing both aesthetics and functionality. According to a study by the Woodworking Machinery Manufacturers of America (WMMA), more than 60% of professional woodworkers have reported starting custom projects as a result of their CNC capabilities. This trend not only promotes individual creativity but also caters to a growing consumer demand for personalized and bespoke products. Additionally, CNC machines can facilitate the production of complex joinery and detailed engravings, allowing woodworkers to push the boundaries of traditional craftsmanship, making each piece a true work of art.

Related Posts

-

Exploring the Future of Best CNC Engraving Machines in 2025 and How to Choose the Right One

-

How to Choose the Best CNC Wood Carving Machine: A Comprehensive Tutorial for Buyers

-

Maximize Your Investment with Top After Sales Support and Repair Cost Tips for Best CNC Router Table

-

5 Incredible Facts About CNC Wood Carving Machines You Must Know

-

Top Strategies for Sourcing the Best CNC Wood Carving Machines Worldwide

-

How to Choose the Right CNC Router for Your Business Needs