Top Industrial CNC Machines: Choosing the Best for Your Business Needs

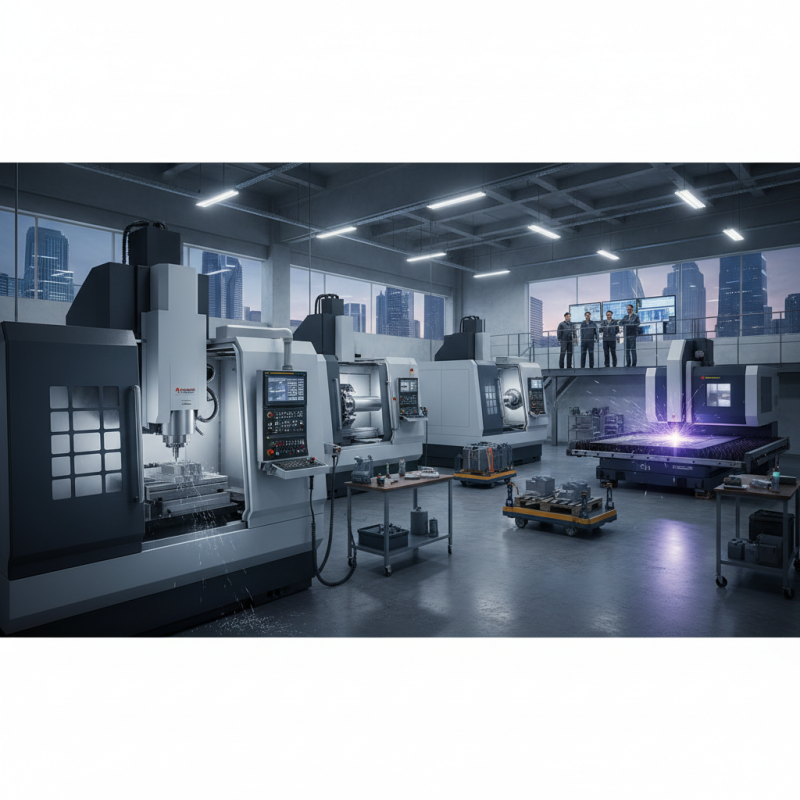

In the rapidly evolving landscape of manufacturing, the significance of industrial CNC (Computer Numerical Control) machines cannot be overstated. These sophisticated tools have revolutionized the way components are designed and produced, allowing for unprecedented levels of precision and efficiency. As businesses strive to meet increasing demands for high-quality products, the need for reliable and advanced industrial CNC solutions has become imperative. This guide seeks to illuminate the key factors that should be considered when selecting the best industrial CNC machines tailored to your specific business needs.

Understanding the various types of industrial CNC machines available on the market is crucial for any business looking to enhance its production capabilities. From milling and turning to plasma and laser cutting, each type of machine offers unique features and benefits suited for different applications. Choosing the right machine not only impacts the quality of manufactured products but also plays a vital role in optimizing manufacturing processes, reducing waste, and ultimately driving down operational costs. With this in mind, we will explore essential criteria such as machine capabilities, compatibility with existing workflows, and overall cost-effectiveness to help you make an informed decision that aligns with your company’s objectives.

Understanding the Basics of CNC Machines in Industrial Applications

CNC (Computer Numerical Control) machines are pivotal in industrial applications, enabling precision and efficiency in manufacturing processes. Understanding the fundamentals of CNC technology is essential for businesses looking to enhance production capabilities. These machines operate by interpreting digital instructions and translating them into precise physical movements. Key components include the controller, which acts as the brain of the machine, and the various tools, such as lathes and milling machines, which perform the actual fabrication tasks.

When selecting CNC machines for your business, consider the specific applications you require. Different machines are designed for various tasks, such as cutting, drilling, or shaping materials. It's crucial to assess the materials you plan to work with and the complexity of the designs you need to produce. This considerations can help streamline your production process and reduce operational costs.

**Tips**: Always seek user-friendly interfaces on CNC machines to facilitate ease of operation, especially if your team is new to this technology. Additionally, investing in training for your staff can significantly enhance productivity and safety. Lastly, don't overlook the importance of maintenance; regular servicing ensures that machines run at optimal levels and prolongs their lifespan.

Key Features to Consider When Selecting a CNC Machine for Your Business

When selecting a CNC machine for your business, it's essential to focus on several key features that can significantly impact your operational efficiency and productivity. One major aspect is the machine's axis configuration. While standard three-axis CNC machines are suitable for basic tasks, companies looking to enhance their capabilities should consider four or five-axis machines that provide more flexibility in tool movement, enabling complex geometries and every angle of reach. According to reports by the International Federation of Robotics, the demand for multi-axis CNC machines has increased by approximately 20% over the last three years, demonstrating a clear trend towards more advanced machining capabilities in the industry.

Another critical feature to evaluate is the machine's build quality and stability. A CNC machine made from high-quality materials will experience less vibration during operation, thereby improving precision and extending the lifespan of both the machine and the tools it uses. Data from the Machine Tool Builders’ Association indicates that investing in a well-constructed CNC system can reduce maintenance costs by 15-25% annually, making it a cost-effective choice in the long run.

**Tip:** When assessing potential CNC machines, prioritize those with user-friendly interfaces and robust software support for programming. This can drastically reduce training time for operators and minimize errors in production. Additionally, consider machines that offer easy upgrades or retrofit options to adapt to future technological advancements without needing a complete system overhaul. This foresight not only saves costs but also ensures longevity and relevance in a rapidly evolving industry.

Top Industrial CNC Machines: Performance Comparison

Comparative Analysis of Top CNC Machine Brands and Their Performance Metrics

When it comes to selecting the best CNC machines for your business, a thorough comparative analysis of various brands is essential. Each brand offers distinct performance metrics, including precision, speed, and versatility, which can significantly impact your production efficiency. Evaluating these factors not only helps in identifying the right machine for your manufacturing needs but also aids in maximizing return on investment.

Tips: Consider creating a scoring system for the performance metrics that matter most to your operations, such as cutting accuracy and cycle time. This method allows for an objective comparison across different brands and models. Also, be sure to review customer feedback and industry reports to gain insight into the long-term reliability and service support of the machines.

Another crucial aspect in the selection process is understanding the types of materials your CNC machine will work with. Some machines excel in soft materials like plastics and wood, while others are built to handle tougher materials like metals. By aligning your machine's capabilities with your specific material requirements, you can enhance productivity and reduce operational costs.

Tips: Don't overlook the importance of ease of use and software compatibility, as these factors can influence your team's learning curve and operational efficiency. Investing in training for your operators can also lead to better utilization of the machine's features and ultimately improve the quality of your output.

Top Industrial CNC Machines: Choosing the Best for Your Business Needs - Comparative Analysis of Top CNC Machine Brands and Their Performance Metrics

| Machine Type | Max Speed (RPM) | Accuracy (mm) | Work Area (mm) | Control System | Price Range (USD) |

|---|---|---|---|---|---|

| CNC Milling Machine | 12000 | 0.01 | 600 x 400 | Fanuc | $20,000 - $50,000 |

| CNC Lathe | 5000 | 0.005 | 300 x 1000 | Siemens | $15,000 - $40,000 |

| CNC Router | 24000 | 0.02 | 1200 x 2400 | Mitsubishi | $25,000 - $60,000 |

| CNC Plasma Cutter | 10000 | 0.1 | 2000 x 6000 | Hypertherm | $10,000 - $30,000 |

| CNC Water Jet | 5000 | 0.1 | 1500 x 3000 | KMT | $30,000 - $70,000 |

Cost-Benefit Analysis: Investing in CNC Machines for Long-term Gains

When considering the acquisition of CNC machines for industrial applications, conducting a thorough cost-benefit analysis is crucial for determining long-term gains. The initial investment in CNC technology can be significant; however, the efficiencies and precision they offer often outweigh the upfront costs. Businesses must evaluate not only the purchase price but also the operational costs, including maintenance, training, and potential downtime, to fully understand the financial implications over time.

One of the primary benefits of CNC machines is their ability to enhance productivity through automation. By reducing the time required for fabricating parts and improving accuracy, CNC machines can lead to lower labor costs and increased output. Moreover, the consistency and repeatability of CNC operations can minimize waste and reduce the risk of errors, further contributing to significant savings over the life of the equipment. Thus, companies should analyze both the tangible and intangible benefits of investing in CNC technology, ultimately justifying their expenditure with long-term operational gains.

Emerging Trends in CNC Technology and Their Impact on Manufacturing Efficiency

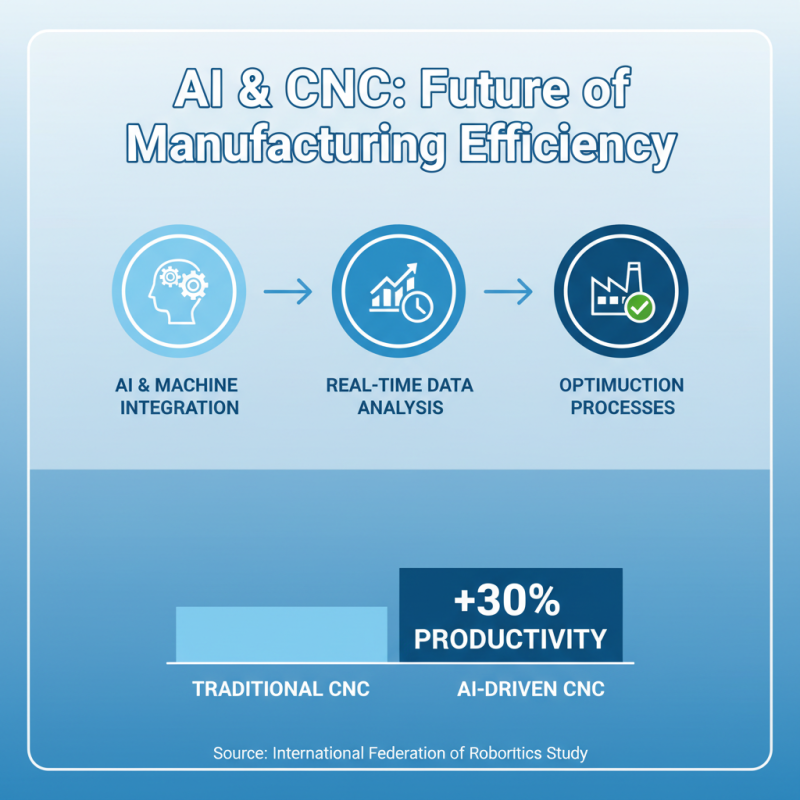

Emerging trends in CNC technology are reshaping the landscape of manufacturing efficiency. One notable development is the integration of artificial intelligence (AI) and machine learning into CNC systems. Reports suggest that AI-driven CNC machines can optimize production processes by analyzing data in real-time, thus significantly reducing downtime and increasing throughput. According to a recent study by the International Federation of Robotics, the implementation of smart automation solutions, including CNC technologies infused with AI, has the potential to enhance productivity by up to 30% in various manufacturing sectors.

In addition to AI, the adoption of advanced materials and additive manufacturing techniques is influencing the capabilities of CNC machines. The ability to work with a broader range of materials and incorporate 3D printing processes allows manufacturers to produce complex geometries with minimal waste. The 2022 Global Additive Manufacturing Market report projected a compound annual growth rate (CAGR) of 23% from 2022 to 2025, emphasizing how these technologies are pushing traditional CNC machining into new territories. By integrating additive manufacturing with CNC operations, businesses can not only reduce lead times but also improve design flexibility and material utilization, ultimately driving greater efficiency in their manufacturing processes.

Related Posts

-

Unlocking the Future of Best CNC Machine Industrial in 2025 Strategies for Global Buyers

-

Ultimate Guide to Choosing the Perfect Home CNC Machine for Your Projects

-

Unlocking Precision: How CNC Industrial Machines Revolutionize Manufacturing Efficiency

-

2025 How to Choose the Best CNC Machine for Your Manufacturing Needs: A Data-Driven Guide

-

2025 Top CNC Machine Metal Innovations for Precision Engineering

-

Top 10 CNC Industrial Machines for Enhanced Precision and Productivity