Exploring the Surge of Woodworking CNC Machines at the 2025 China Import and Export Fair

The 2025 China Import and Export Fair, also known as the 138th Canton Fair, is poised to be a significant platform for showcasing innovations in various industries, particularly in woodworking technologies. Among the highlights of this event is the surge of woodworking CNC machines, which are transforming the landscape of furniture and cabinetry production.

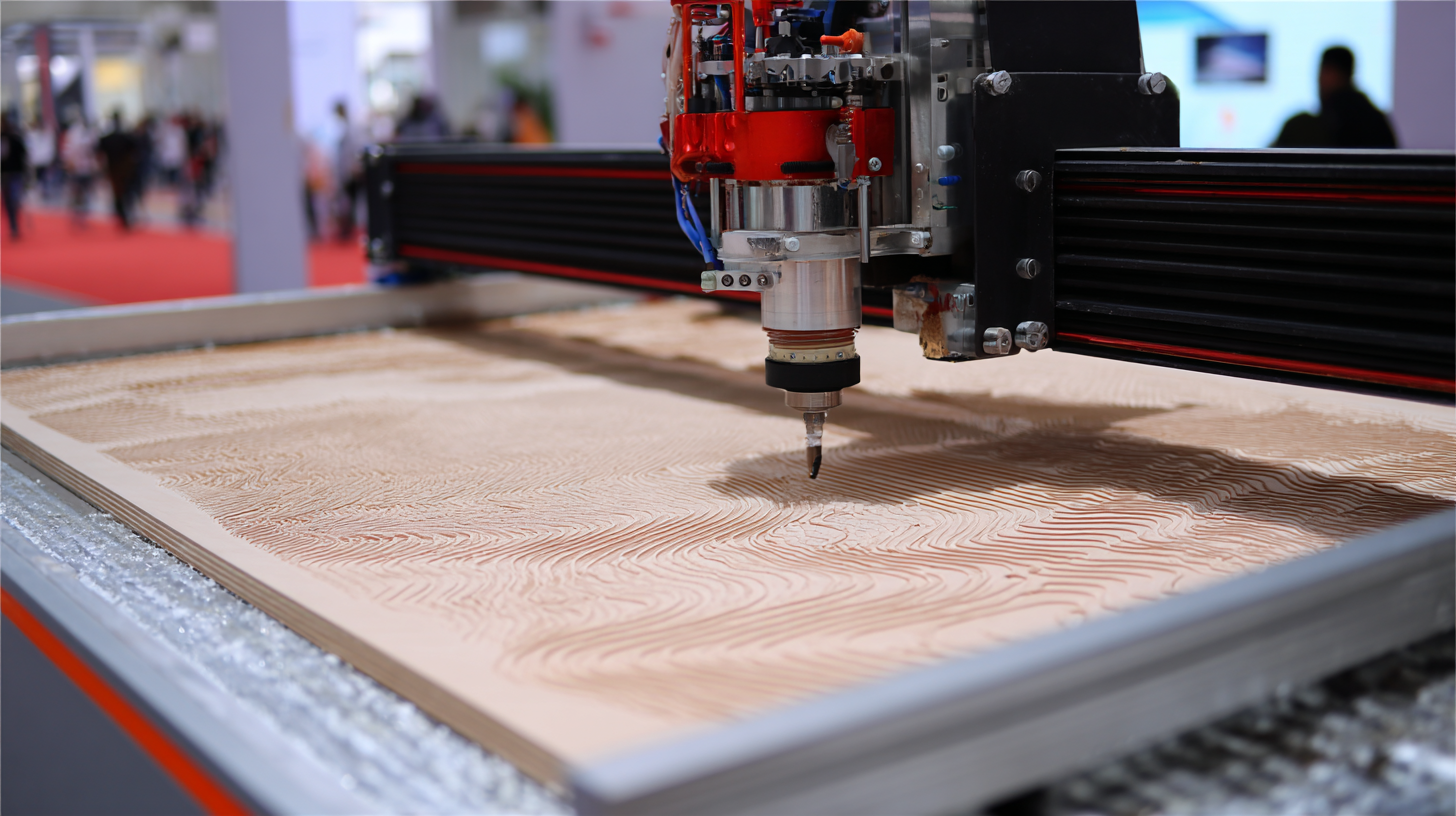

These advanced machines combine precision with efficiency, allowing artisans and manufacturers alike to create intricate designs with minimal waste. The growing interest in woodworking CNC machines at the fair not only reflects the increasing demand for automation in traditional crafts but also underscores China's pivotal role in global manufacturing trends. Attendees can expect to see cutting-edge models that push the boundaries of creativity and production capabilities, making this an exciting time for both seasoned professionals and newcomers in the woodworking sector.

These advanced machines combine precision with efficiency, allowing artisans and manufacturers alike to create intricate designs with minimal waste. The growing interest in woodworking CNC machines at the fair not only reflects the increasing demand for automation in traditional crafts but also underscores China's pivotal role in global manufacturing trends. Attendees can expect to see cutting-edge models that push the boundaries of creativity and production capabilities, making this an exciting time for both seasoned professionals and newcomers in the woodworking sector.

The Rise of Woodworking CNC Machines in China: Market Trends and Projections for 2025

The woodworking CNC machine market in China is experiencing significant growth, reflecting broader trends in the global market. In 2025, the global woodworking machinery market is projected to expand from $5.23 billion to $7.88 billion by 2032, demonstrating a compound annual growth rate (CAGR) of 6.0%. This surge can be attributed to advancements in technology and increasing demand for precision woodworking solutions across various industries.

In China, the rise of woodworking CNC machines is fueled by the country's robust furniture manufacturing sector and a growing emphasis on automation. As manufacturers seek to enhance efficiency and reduce labor costs, the adoption of CNC machines is becoming a strategic priority. Reports indicate that businesses leveraging CNC technology can achieve significant improvements in production speed and product quality. As the industry evolves, investments in innovative woodworking solutions are likely to play a crucial role in maintaining competitive advantages in both domestic and international markets.

Innovations Driving the Growth of Woodworking CNC Technologies at the 2025 Fair

At the 2025 China Import and Export Fair, woodworking CNC technologies are expected to showcase dramatic innovations that are reshaping the woodworking industry. Notably, advancements in automation and precision are taking center stage, enabling manufacturers to enhance production efficiency while maintaining high quality. These innovations not only streamline operations but also allow for greater customization, meeting the diverse needs of consumers and businesses alike.

As China continues on its trajectory to become a leading innovator in advanced manufacturing, the integration of cutting-edge CNC technologies in woodworking is a testament to its growing capabilities. The emphasis on technological breakthroughs is evident, with various exhibitors poised to unveil new machines and software designed to elevate woodworking processes. This event will serve as a platform for industry leaders to exchange ideas and explore collaborative opportunities, further driving the growth of woodworking CNC technologies worldwide.

Impact of Automation on the Woodworking Industry: Efficiency Gains and Cost Reduction

As woodworking CNC machines gain traction in the industry, their impact on automation cannot be understated. The integration of these machines has revolutionized traditional woodworking practices, enabling manufacturers to achieve unprecedented efficiency gains. High precision and speed are now attainable, significantly reducing the time taken from design to finished product. This shift not only streamlines production processes but also allows craftsmen to focus on creative aspects, enhancing the overall quality of the output.

Moreover, the cost reductions associated with adopting CNC technology are substantial. By minimizing material waste through precise cutting and optimizing labor requirements, companies can significantly lower their operational costs. This financial relief is particularly beneficial for small to medium-sized enterprises, enabling them to compete more effectively in a challenging market. As manufacturers increasingly recognize these advantages, the woodworking industry is poised for a transformation driven by automation that promises to reshape its future.

Key Players in the Woodworking CNC Machine Market: Insights and Strategies for 2025

The woodworking CNC machine market is poised for significant growth, projected to expand from $5.23 billion in 2025 to $7.88 billion by 2032, reflecting a robust annual growth rate of 6.0%. This surge highlights the increasing demand for precision and efficiency in woodworking processes, driven by advances in technology and a growing preference for automation in manufacturing.

Key players in this market are actively adopting various strategies to capitalize on this trend. Investments in research and development are crucial, as companies aim to enhance machine capabilities and integrate smart technologies. Moreover, partnerships and collaborations are becoming essential, enabling firms to leverage each other's strengths in production and market penetration. As the industry evolves, understanding the competitive landscape and adopting agile responses to market demands will be critical for success in the rapidly changing woodworking CNC machine sector.

Exploring the Surge of Woodworking CNC Machines at the 2025 China Import and Export Fair

| Market Segment | 2024 Market Size (USD) | 2025 Projected Growth (%) | Key Application Areas |

|---|---|---|---|

| Entry-Level CNC Machines | $150 million | 12% | Hobbyist Projects, Small Workshops |

| Mid-Range CNC Machines | $300 million | 9% | Furniture Production, Cabinet Making |

| High-End CNC Machines | $500 million | 15% | Interior Design, Custom Manufacturing |

| CNC Routers | $400 million | 10% | Sign Making, Sculptures |

| CNC Laser Cutters | $250 million | 8% | Artistic Crafts, Industrial Parts |

Future Challenges and Opportunities for Woodworking CNC Manufacturers in China

The woodworking CNC (Computer Numerical Control) industry in China is on the brink of transformative growth as it presents both challenges and opportunities for manufacturers. One of the primary challenges lies in the rapid technological advancements. As consumers demand more precision and customization, manufacturers must invest in state-of-the-art technology to keep pace with evolving market expectations. This can be a significant financial commitment, particularly for smaller companies that may struggle to afford the latest machinery and software upgrades.

On the other hand, this environment of technological evolution offers ample opportunities for woodworking CNC manufacturers. By embracing innovation, companies can differentiate themselves in a competitive market. The rising trend of personalized woodworking solutions opens new avenues for businesses willing to adapt. Furthermore, as sustainability becomes increasingly paramount, manufacturers can pioneer eco-friendly practices and products, thereby appealing to a growing segment of environmentally-conscious consumers. Overall, the future landscape for woodworking CNC manufacturers in China will be shaped by their ability to navigate these challenges while capitalizing on emerging opportunities.

Woodworking CNC Machines Growth Forecast (2023-2025)

This chart illustrates the projected growth in the sales of woodworking CNC machines from 2023 to 2025. The data shows a significant increase in units sold, indicating a promising market for manufacturers in China as they prepare for future challenges and opportunities.

Related Posts

-

5 Incredible Facts About CNC Wood Carving Machines You Must Know

-

Unlocking Creativity with CNC Wood Carving Machines and Their Unique Advantages

-

5 Key Benefits of Investing in Wood CNC Machines for Global Manufacturers

-

Exploring Innovative Examples of CNC Industrial Machine Applications

-

5 Essential Tips for Choosing the Best Desktop CNC Machine for Your Business

-

How to Choose the Best CNC Wood Carving Machine: A Comprehensive Tutorial for Buyers