How to Choose the Best Desktop CNC Machine for Your Needs

When it comes to precision crafting and manufacturing, choosing the right CNC (Computer Numerical Control) machine can make all the difference. If you’re considering a desktop CNC machine, you’re likely interested in something compact, efficient, and capable of handling intricate projects. This guide will walk you through the essential factors to consider when selecting the best desktop CNC machine to meet your needs.

What is a Desktop CNC Machine?

A desktop CNC machine is a compact version of larger industrial CNC machines. Designed for hobbyists, small businesses, and home workshops, these machines offer precision and control in a smaller, more manageable size. They can handle a variety of materials, including wood, plastic, and metal, making them versatile tools for a range of applications.

Key Factors to Consider

1. Define Your Needs and Goals

Before diving into the technical specifications, it’s important to define what you want to achieve with your desktop CNC machine. Are you looking for a machine for detailed woodworking, small-scale metalworking, or prototyping? Understanding your primary use case will help you narrow down your options and choose a machine that best fits your needs.

2. Evaluate Machine Size and Work Area

The size of the desktop CNC machine and its work area are crucial factors. Depending on the size of the projects you plan to undertake, you’ll need to select a machine with an adequate work area. Ensure that the dimensions of the machine can accommodate your largest planned projects, while also fitting comfortably in your workspace.

3. Consider Material Compatibility

Different CNC machines are designed to handle different materials. If you plan to work with various types of materials like wood, acrylic, or aluminum, make sure the machine you choose can handle these materials. Some machines are better suited for heavy-duty CNC machining, while others are designed for lighter tasks. Check the machine’s specifications to confirm its compatibility with your intended materials.

4. Check the Machine’s Precision and Accuracy

Precision is a key factor in CNC machining. Look for a desktop CNC machine that offers high accuracy and repeatability. The machine’s specifications should indicate its precision levels, often measured in microns or millimeters. A machine with higher precision will produce better quality work and reduce the need for manual adjustments.

5. Look for Robust Construction and Build Quality

A desktop CNC machine should be built to last, especially if you’re engaging in heavy-duty CNC machining. Look for machines made from durable materials such as steel or aluminum. The build quality will impact the machine’s stability, accuracy, and overall performance. A well-constructed machine will handle long-term use and various types of projects more effectively.

6. Explore Software Compatibility

The software that comes with or is compatible with your desktop CNC machine plays a significant role in its functionality. Make sure the machine supports popular CNC programming software or has intuitive software for easy design and control. The software should be user-friendly and offer the necessary features for your specific applications.

7. Assess the Machine’s Ease of Use and Setup

User-friendliness is important, especially if you’re new to CNC machining. Look for machines with straightforward setup processes and intuitive controls. Some machines come with comprehensive manuals or online resources to help you get started. A machine that is easy to use will save you time and reduce frustration.

8. Consider Support and Warranty

Reliable customer support and a good warranty are essential when investing in a CNC machine. Check if the manufacturer offers robust customer service, technical support, and a warranty period that covers potential issues. A good warranty will give you peace of mind and protect your investment.

FAQ: CAMaster Desktop CNC Machine

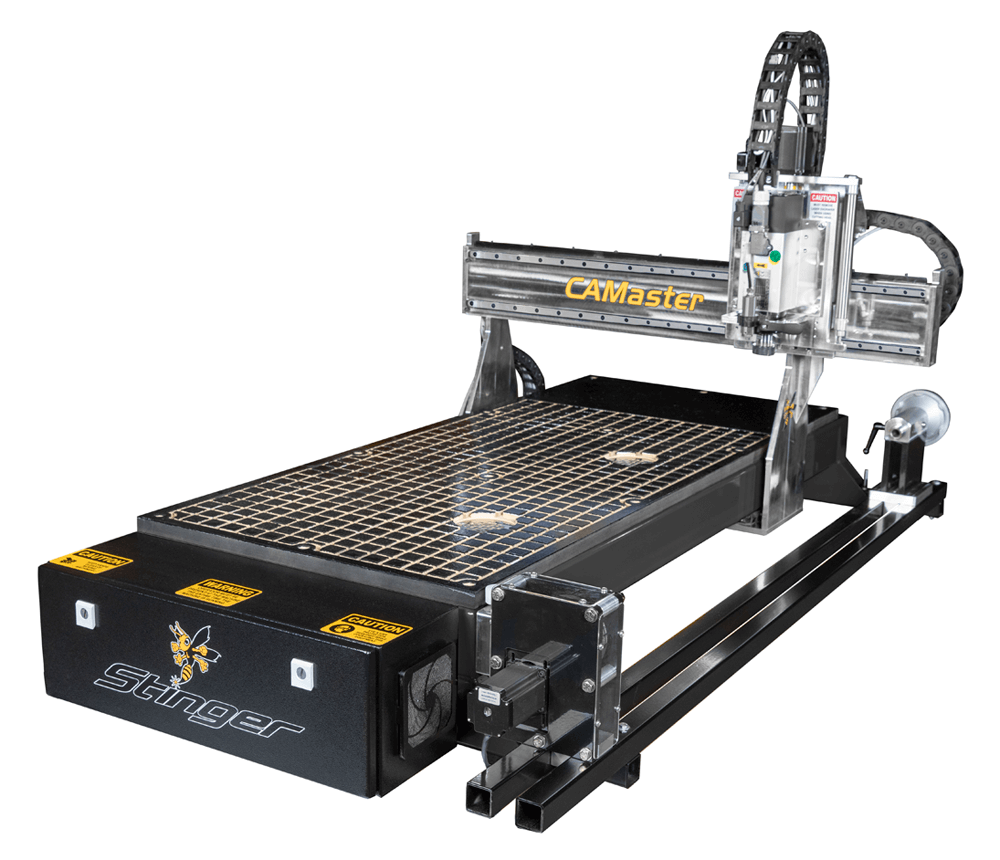

- What is the CAMaster Desktop CNC Router?

The CAMaster Desktop CNC Router is a compact, robust machine designed for hobbyists and production environments. It features a welded steel frame, and high-precision components, and comes fully assembled from our facility in Cartersville, Georgia.

- What size is the cutting area of the CAMaster Desktop CNC Machine?

The CAMaster Desktop CNC Router has a cutting area of 2’ x 4’, providing ample space for various projects.

- What software is included with the CAMaster Desktop CNC Machine?

It comes with Vectric’s VCarve Pro design software, offering a comprehensive design and cutting solution.

- What are the standard features of the CAMaster Desktop CNC Router?

Standard features include a welded steel frame, Centroid PLC Controller, Windows 10 PRO PC, precision rails and bearings, dust boot, and free tech support for the machine’s lifetime.

- Is the CAMaster Desktop CNC Router easy to set up and use?

Yes, the machine is shipped fully assembled and tested, making it a turnkey solution for users. It includes user-friendly software and comprehensive support.

Conclusion

Choosing the best desktop CNC machine involves careful consideration of your specific needs and the machine’s capabilities. By evaluating factors such as machine size, material compatibility, precision, build quality, software compatibility, ease of use, and support, you can find a machine that meets your requirements and enhances your projects. For those seeking reliable and high-performing CNC machines, CAMaster is a brand you can trust to deliver quality and precision in every cut.

Investing in the right desktop CNC machine can elevate your crafting and manufacturing efforts, providing you with the tools to bring your designs to life with accuracy and efficiency. Whether you’re engaging in detailed woodworking, metalworking, or prototyping, selecting a machine that aligns with your needs will ensure successful and satisfying results.

Want to upgrade your CNC workflow?

Discover our industrial-grade CNC solutions tailored to your needs. Learn more →